High Speed Roll Slitting Services

CS Hyde Company’s roll slitting services feature the use of high-speed, computerized, top of the line slitting equipment. We can maintain super-tight tolerances of (±) 1/32″ or tighter depending on the material and can slit substrates with or without adhesives. Our onsite equipment, in combination with years of operator experience, enables us to cut rolls from .125″ wide up to 60″ and ranging from .0005″ to .060″ in thickness.

Slit and shipped without the struggle

No custom slitting fees or minimum quantities on stock materials. You can order a single roll or thousands, with a turn-around time of just a few business days, and daily carrier pick up for international, domestic, and overnight shipping.

Need a roll fast? Standard width roll products can be sourced Online- click, slit, & shipped directly to your facility

Types of roll materials we slit

CS Hyde is capable of slitting custom width 3M VHB foam & transfer tapes, film & fabric adhesive tapes, plastic films, fabrics, and silicone rubber products. Some of the materials we most commonly slit include Teflon™ Fluoroplastic(PTFE) ,Kapton®(polyimide), UHMW, high-temperature fiberglass and foil tapes, PTFE coated tapes, Mylar® Polyester, as well as a wide variety of PTFE coated and non-coated fabrics.

CS Hyde also provides consignment slitting services for customer supplied materials, as long as material specifications meet our machine capabilities.

The advantages of custom roll slitting:

Taking advantage of custom roll slitting enables you to limit material waste produced in your application. Custom width slitting enables you to accurately fit your substrate into your design without additional fabrication. For example, custom width roll slitting is ideal for masking applications when only specific area masking is needed during a coating or painting process. Other applications include equipment specific applications like covering hot heat sources or hot wires commonly found on bagging or sealing machines. No matter the application or industry, high speed roll slitting services are an ideal resource for custom design requirements.

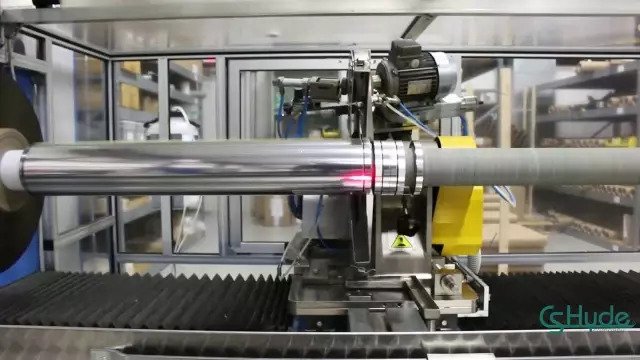

Watch high speed slitting in motion!

Custom Slitting Services Capabilities

- Industry Focus

-

Industrial

Aerospace

ChemicalFood

Plastic

- Materials

-

Tapes

Films

Fabric

3M®

ABS

Acetal

DuPont®

Fiberglass

Fluropolymers

Foil

HDPE

Kapton®

Kynar®

MetalPEEK

PVDF

Rubber

Silicone Sponge

Silicone

Solef®

Strip n Stick®

Teflon™ Fluoroplastic

UHMW

Ultem®

Urethane

VHB

We also work with customer supplied materials

- Features

-

Adhesive

No Adhesive

- Automation Capabilities

-

Computer Controlled Process

- Slitting Equipment

-

Numerous Slitting machines for fast turnaround

- Production Volume

-

Min

1 unit

Prototype

Low Volume

Small RunMax

1,000’s units

High Volume

Large Run

- Typical Lead Times Available

-

Min

1 Day

- Material Width

-

Min

.125 in

3.175 mmMax

60 in

1,524 mm

- O.D.

-

Max

10 in

254 mm

- Material Thickness

-

Min

.0005 in

.0127 mmMax

.50 in

12.5 mm

- Core Sizes Available

-

1 in

1.5 in3 in

6 in

- Tolerance (+/-)

-

±1/32 in

Tighter Tolerances Available Upon Request

- Additional Services Provided

-

Belting

Die CuttingLaminating

Sheeting

- Areas Served

-

Ship National & International

- Industry Standards

-

ASTM American Society for Testing and Materials

Mil-Spec Military Specifications

RoHS Restriction Of Hazardous Substances (Compliant)

WEEEProper Disposal of all electronic equipment via contract with Waste Management

Woman Owned Business

Small Business

- File Formats

-

BMP Bit Mapped Graphics

GIF Graphics Interchange Format

JPG or JEPG Joint Photographic Experts GroupPDF Portable Document Format

TIFF Tagged Image File Format